Elevator Ropes

Products

Showing all 2 results

-

HOIST & COMPENSATING ROPE

Read more8X19S(9-9-1)

-

HOIST & COMPENSATING ROPE

Read more8x19S(9-9-1)+IWRC

Showing all 2 results

Elevator Wire Ropes, unlike wire ropes for other application, demand much closer dimensional

tolerances and stringent material quality levels to meet its tough safety requirements.

Usha Martin has been present in the elevator wire rope business for more than fifty years. Our wire rope are designed to meet the quality levels of almost all the national and international standards. Our experience of producing the highest quality products and our continuous effort for improvement permit us to satisfy even the most demanding product standards and OEM specifications.

Our product mix includes the Hoist Ropes, Compensating Ropes, Governor Ropes & Control Ropes used in Traction Drive Elevators and Roped Hydraulic Lifts.

Product Design

The prerequisite for a good rope is good design. Usha Martin Elevator ropes are designed using a highly effective and specialized rope design system. This system combined with years of experience ensures that every rope is made with optimum design.

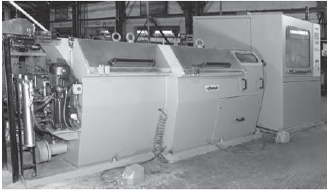

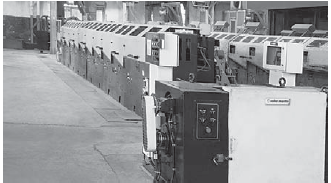

Latest Machinery

Besides rope design and good raw material quality the production equipment effect product quality the most.

We have an in-house machine design and manufacturing facilities which ensures that we have customized equipments incorporating latest technology.

Raw Material Quality

Good raw material quality lays the foundation of high quality in the finished rope. Usha Martin is fully backward integrated having its own iron ore, coal mines with state-of-the-art steel melting, refining & rolling facilities. Steel for Elevator Steel Wire ropes is tailor-made to achieve the highest levels of strength, ductility and endurance.

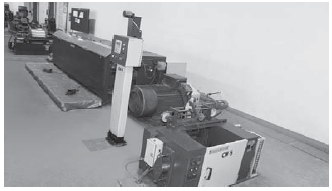

Bending Fatigue Appraisal

Bend fatigue resistance is the ability of the wire rope to withstand repeated bending over drum/pulley under constant or fluctuating load. Our ropes including Elevator wire ropes, Lift elevator wire ropes, elevator steel wire ropes and all other types of wire ropes undergo a ’comprehensive fatigue testing program’ which has been devised not only to ensure that our ropes consistently deliver performance but also to provide information for product improvement and development.

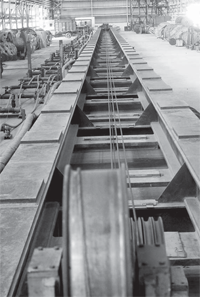

Pre-stretching

It is a specialized process opted for removing the construction stretch (a permanent stretch which occurs shortly after the elevator rope is installed) from the wire rope. Our pre-stretched ropes are processed off-line , on a specially designed P/S bed, utilizing a longer length of rope and subjecting it to suitable load for sufficient number of cycles until it stabilizes. This process has been found to be the most effective in reducing the constructional stretch of a wire and is much superior to on-line pre-stretching.

Optimum Performance and Consistency

A simple way to ensure performance and consistency is to make sure that you are using Usha Martin Rope.

We at Balbir Singh & Sons are elevator ropes suppliers in India.

Unique Identification Tag

Maintenance

The wires of all elevator ropes produced at Usha martin are lubricated during stranding process with specialized lubricant and a controlled wiping is employed to regulate its quantity on the finished wire rope. The type of lubricant is carefully selected for each category of Elevator rope considering long service life of these wire ropes and further to ensure that traction is not affected adversely during usage. The natural fibre core is also impregnated with a compatible lubricant to protect the same during its storage and usage.

The lubricant applied during production, however, gradually diminishes during usage and requires to be replenished periodically with a suitable lubricant. The field lubricant is necessary to reduce wear of rope and sheaves , minimize friction between wires, protect wires from corrosion and increase service life of the wire rope.

Avoid :

- Excessive Lubrication of hoist ropes- check traction, acceleration & deceleration after relubrication by running through complete cycle sufficient number of times.

- Lubrication of governor ropes- it may interfere with the designed safety function of the device . Check OEM’s recommendation.