PP/Polyester mixed rope

Resistance to Abrasion

- Combination of high tenacity polyolefin and polyester yarns.

- Produced as per OCIMF guidelines.

- Higher strength to weight ratio than Nylon ropes.

- Cost effective.

- Resistance to corrosion effect of marine conditions.

| Size Dia. (mm) | Dia. (inch) | Weight (kgs/100m) | Breaking Strength (kgf) |

|---|---|---|---|

| 40 | 5 | 88.40 | 30000 |

| 48 | 6 | 128.00 | 46290 |

| 52 | 6-1/2 | 150.00 | 54300 |

| 56 | 7 | 172.00 | 62800 |

| 64 | 8 | 225.00 | 82600 |

| 72 | 9 | 285.00 | 102000 |

| 80 | 10 | 352.00 | 125500 |

| 88 | 11 | 502.00 | 156000 |

| 96 | 12 | 598.00 | 185000 |

| 104 | 13 | 701.00 | 216000 |

| 112 | 14 | 813.00 | 250000 |

| 120 | 15 | 933.00 | 286000 |

| 128 | 16 | 1060.00 | 325400 |

| 136 | 17 | 1200.00 | 365000 |

| 144 | 18 | 1345.00 | 405000 |

Note: The minimum breaking load (MBL) should never be consider as the safe working load of the rope. For the method of calculating safe working load please refer of safety= Breaking Force/6

Key Features

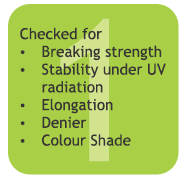

Quality Control Process

Stringent Quality Checks

Yarn Development

Rope Making