Inspection Criteria

Why must be Inspected & Examined

Wire ropes like most other items are perishable with a limited life. As time elapses during usage, the properties of constituent wires and the wire rope changes. The breaking strength of the wire rope, for example, decreases because of :

- Loss in steel area due to abrasion and corrosion

- By wire breaks due to fatigue

- Other reasons like mechanical damage, thermal damage, deformation of wire due to rotation, jerk etc

This loss in strength eventually results in sudden failure of the wire rope and may become a possible safety hazard.

Hence wire ropes must be inspected properly at suitable intervals to “Supervise the normal process of deterioration to enable the user to remove it from service before abrupt failure takes place”

When to Inspect

Wire ropes must be inspected at the start of each shift, however it must be inspected more frequently for a few days / weeks

- whenever rope is installed – to ensure that the rope has been correctly installed

- whenever it is felt that the condition of the wire rope is deteriorating – to ensure rope discard at the right time

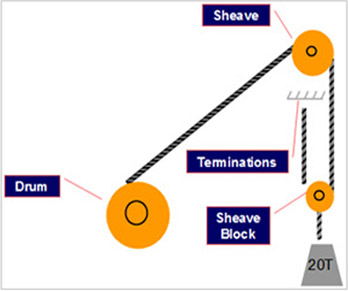

The inspection must be visual assessment of the critical areas of the wire rope (without removing it from installation) for example :

- the portion which is passing over sheaves and drums more frequently

- the end terminations

- the portion which has shown some mechanical damage

When to Examine

Examination, on the other hand, is a careful and thorough assessment of the wire rope and includes :

- Visual Examination – to reveal the external and more particularly the internal condition of the rope.

- Measurement – like rope diameter, lay length

- Non Destructive Testing

- Critical Assessment of the end fittings and terminations

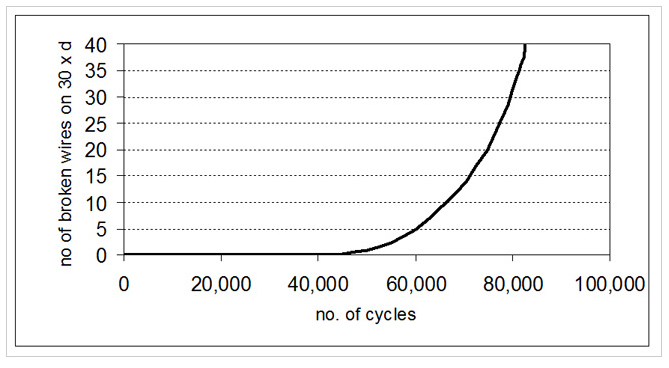

Examination must be carried out at regular intervals and the schedule must be selected to ensure detection of damage at an early stage. The interval must be reduced upon observing first broken wire or any other damage because the rope deteriorates at a rapid rate after first wire breakage.

- Installation of a new rope type , no previous record of performance

- First broken wire being observed during routine inspection / examination

- Any other damage being observed during routine inspection / examination

- If the rope suffers overload , shock or twist

- If it is put back in service after a long period in stores

- If end fittings / termination or a lifting device has been changed

- If the rope and / or any other associated device has been dismantled and re-assembled

When to Remove

- Must be discarded when the no. of broken wires has reached or exceeded the permissible number of wire breaks within a specified rope length ( usually 10xd or 30xd ) as per any national or international standard.

- Must also be discarded if the no. of broken wires are concentrated although the total wire breaks are within the specified permissible limit.

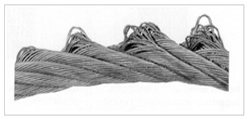

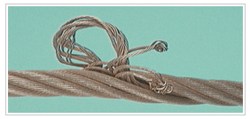

- Must be discarded if the rope has developed Malformation / Deformation such as Loop , Kink, Birdcage, Core Protrusion or any other form of serious damage to the wire rope.

LOOP

CORE PROTRUSION

BIRD-CAGE FORMATION

KINK

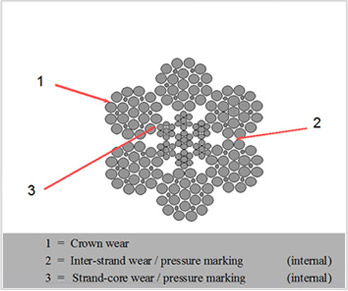

Areas of wear

Areas of deterioration

- Witness passage of rope through complete operating cycle

- Determine areas where greatest deterioration is likely to occur

(e. g. coinciding with pick-up of load)

External wear

- Normal wear on strand crowns

- Relatively easy to see & assess

Affected by the Appliance / Machine / Duty

- Rope Tension

- Size of drum / sheave

- Number of sheaves

- Condition of drum / sheave(s)

- Rate of acceleration / deceleration

- Momentum of sheave(s) / roller(s)

- Fleet angle & spooling arrangement at drum

Can also be affected by environmental & Application conditions, e.g.

- Abrasive dust

- Lack of lubricant / dressing in service

Internal wear

Unable to see without opening rope up

Results from pressure, stress and friction

- Level of rope tension and amplitude

- Bending ratio and frequency of bending

- Amount of lubricant / dressing

Methodology

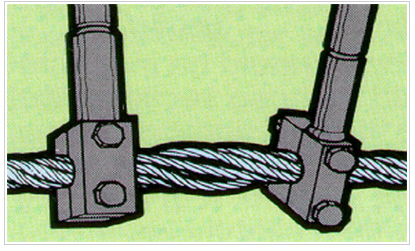

- Take two grips, the inside groove having been made from some soft material like wood or nylon.

- Tighten these grips on to the rope, 500 mm apart, in the region which appears to have the maximum wear mark or the region which comes most frequently during the bending zone.

- Slightly rotate the two grips, say around 30°, in opposite direction to make the rope flex a little bit.

- Wire breaks, if any, in the inside zone shall pop out.