IS:2762/82 IS:5245/1pt ||

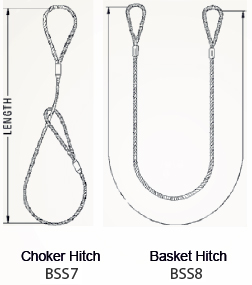

| Min. Rope Size | Vertical Lift | Basket Lift | Choker Lift |

|---|---|---|---|

| mm | kg | kg | kg |

| 3 | 70 | 140 | 50 |

| 4 | 130 | 260 | 100 |

| 5 | 200 | 400 | 150 |

| 6 | 250 | 500 | 190 |

| 8 | 550 | 1100 | 410 |

| 9 | 670 | 1340 | 500 |

| 10 | 800 | 1600 | 600 |

| 11 | 1000 | 2000 | 750 |

| 12 | 1200 | 2400 | 900 |

| 13 | 1400 | 2800 | 1050 |

| 14 | 1750 | 3500 | 1300 |

| 16 | 2000 | 4000 | 1500 |

| 18 | 2500 | 5000 | 1875 |

| 19 | 3000 | 6000 | 2250 |

| 20 | 3300 | 6600 | 2250 |

| 22 | 4000 | 8000 | 3000 |

| 24 | 4600 | 9200 | 3450 |

| 25 | 5000 | 10000 | 3750 |

| 29 | 6500 | 13000 | 4875 |

| 32 | 8000 | 16000 | 6000 |

| 35 | 9200 | 18400 | 6900 |

| 36 | 10400 | 20800 | 7800 |

| 38 | 12000 | 24000 | 9000 |

| 40 | 12700 | 25400 | 9525 |

| 44 | 16700 | 33400 | 12525 |

| 48 | 20000 | 40000 | 15000 |

| 52 | 23000 | 46000 | 17250 |

Dos and Donts for steel wire rope slings

Here are some important dos and don’ts for using steel wire rope slings safely:

Dos:

- Check the weight of the load to be lifted.

- Inspect slings before use and discard any that are defective.

- Protect slings from sharp corners by using suitable packing materials like rubber or wood.

- Use protective gloves when handling steel wire rope slings.

- Store slings in a dry place when not in use.

Don’ts:

- Don’t exceed the stated SWL (Safe Working Load).

- Don’t use slings with kinking, crushing, birdcaging, or other damage that distorts the original rope construction.

- Don’t use slings with more than 10 randomly broken wires in one rope lay, or 5 wires in one strand in one rope lay.

- Don’t use slings with severe wear, abrasion, or scraping.

- Don’t bend slings over corners.

- Don’t exceed 120 degrees when using multi-legged wire rope slings.

- Don’t drag slings along the floor.

- Never allow the load to be carried over the heads of other people.

- Never ride on the load.

- Never join slings by knotting, always use a shackle.

- Never shorten slings by knotting.

Following these guidelines will help ensure safe and effective use of steel wire rope slings.