General Discard Criteria : Crane Wire Ropes

- Rope diameter reduction> 7% of NRD, only due to external wear.

- Rope diameter reduction> 3% of NRD for rotation resistant ropes and > 10% for other ropes due to reasons other than external wear.

- For single layer (6 and 8 strands) and parallel closed ropes if number of visible broken wires exceed 4% of total load bearing in all outer stands of the rope, over a length of 6d or 8% in 30d.

- For rotation resistant ropes if number of visible broken wires exceed 2 over a length of 6d or 4 in 30d.

- Concentrated close group of broken wires in a length of 6d or in one strand.

- Wire break in the strand valley indicate internal rope deterioration requiring closer inspection of the rope, 2 or more valley breaks in the 6 x d requires discard.

- Broken wires adjacent to, the termination, requires the termination to be remade by shortening the rope otherwise the rope shall be discarded.

- Localized distortion, damage crushing, kink, loop, birdcage formation.

- Localized core or stand protrusion.

- Localized rope diameter reduction or lay variation associated with waviness.

- Collapsed core or complete fracture of one strand.

- Sign of sever corrosion or pitting.

- Damage due to heat.

Note:

For discard of ropes other than crane wire ropes relevant codes/standard should be referred. The rope should be examined by a competent person who should always refer relevant code/recommendation/ standard for deciding rope discard.

Storage Handling & Installation Procedure

Crane Ropes, like any machine or spares, deteriorate during storage as well as in service. Therefore, the assurance of safety and economy in use of the equipment, dictates the requirement for a procedure of proper storage, handling & installation of Crane ropes.

Storage

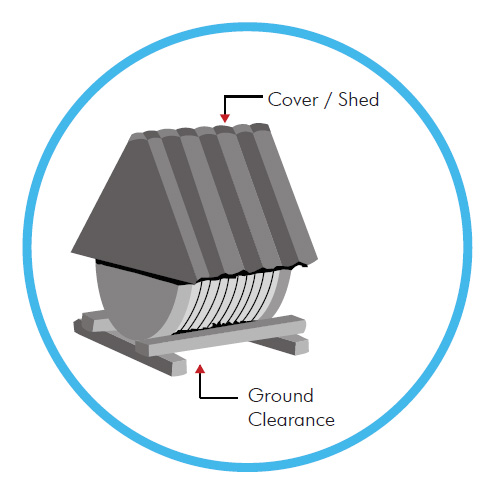

- Store rope in a clean, dry, well ventilated, dust free undercover location.

- Cover the rope with waterproof material and/or canopy, if not stored inside.

- Storage should be free from steam, chemical fumes or any other corrosive agent.

- Avoid direct contact of rope with floor.

- Place reels, preferably over A-frame or cradle and allow flow of air under the reel.

- Avoid rope exposure to elevated temperatures.

- Avoid handling damages to wire ropes.

- Ensure that tag/marking is intact and follow ‘first in, first out’ principle.

- Inspect rope periodically and, apply suitable rope dressing compatible with manufactured lubricant, whenever necessary.

- Rotate reel periodically, say after every 3 months, particularly in warm environment.

Handling & Installation

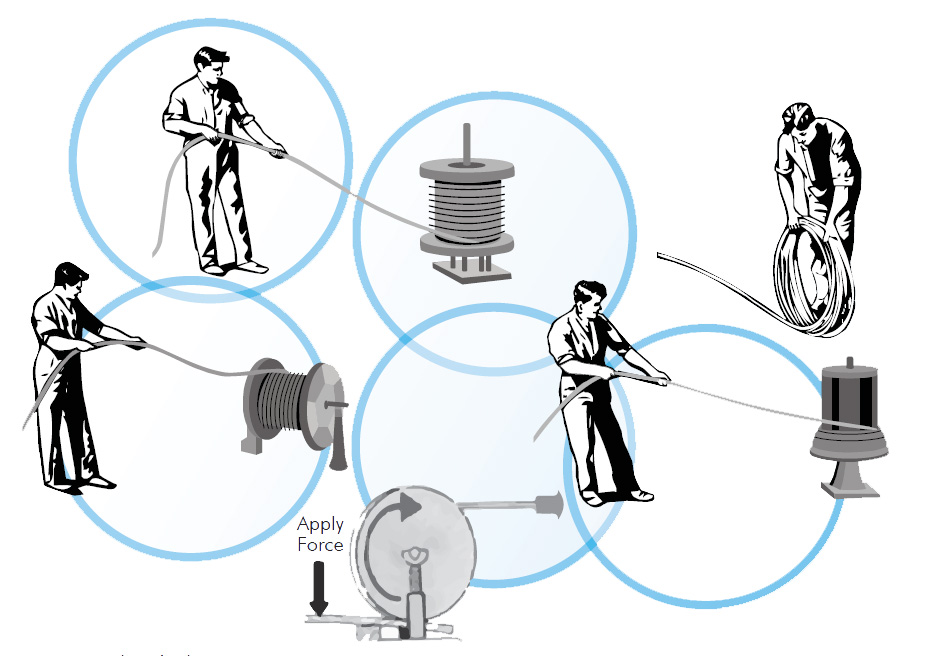

- Never pull out rope from stationary coil.

- Place rope coil on ground and roll out straight.

- If heavy, place coil on turntable and pull the end away from coil.

- Prevent contamination with dust, grit, moisture, chemicals and other harmful material.

- Put a shaft, of adequate strength, through reel bore and place the reel in a suitable stand.

- Allow reel to rotate freely and be braked to avoid overrun.

- Provide back-tension for multi-layer spooling and ensure to wind tightly, particularly the bottom layer.

- Maintain constant tension while reeving and avoid layer cross-over.

- Avoid formation of loops and / or kinks.

- Avoid reverse bend during reeving. Wind / unwind ‘top to top’ or ‘bottom to bottom’.

- Take special care while releasing the outboard end of rope from supplied reel or coil.

- Maintain fleet angle at minimum during installation.