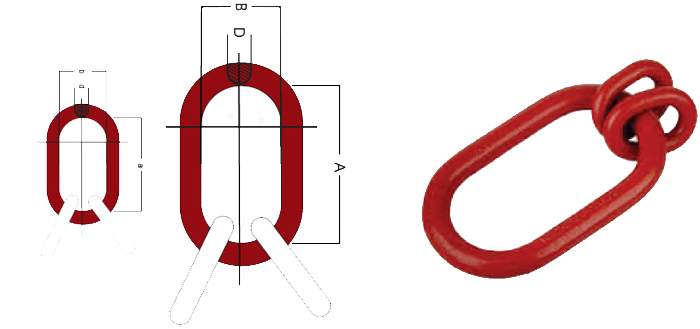

Master ring assembly welded alloy steel is one of the most used lifting accessories used in the lifting industry. There are various specific features of a master ring assembly welded alloy steel, including 2 times more working load limit than other master rings, rust and corrosion-free, easy to operate, etc. A master ring assembly welded alloy steel is an oblong shape chain made of forged steel material and has high tensile strength. Every master ring assembly welded alloy steel supplier sells master rings with two min rings or sub-links attached to the master ring, which helps distribute the lifting load equally. Master ring assembly welded alloy steel can be used 3 or 4 times with a multi-legged sling. In addition, it is vital to check that the master ring and other components have the same grade load and working capacity before buying them from master ring assembly welded alloy steel manufacturers in India.

| WLL (t) | Size (D*A*B) (mm) | Weight (kg) |

|---|---|---|

| 5T | 22*160*90-16*70*34 | 2.2 |

| 10T | 26*180*100-18*85*40 | 3.41 |

| 15T | 32*200*110-22*115*50 | 6.1 |

| 20T | 38*267*133-28*140*65 | 11.5 |

| 25T | 40*300*160-32*150*75 | 15.11 |

| 30T | 45*305*152-36*180*100 | 21 |

| 35T | 51*355*178-38*180*100 | 27.8 |

| 40T | 56*400*200-40*180*100 | 35.04 |

| 50T | 63*406*203-45*200*110 | 47.66 |

| 80T | 75*457*228-60*300*150 | 93.1 |